MetLase transforms manufacturing performance by combining intelligent automation, digital optimisation, and precision mechanical systems.

From design to production and beyond, we solve critical process challenges across the product lifecycle.

Our custom and turnkey solutions streamline operations, reduce risk, and unlock smarter, faster performance—helping manufacturers move with agility and deliver consistent, high-quality outcomes.

We help manufacturers move faster, operate smarter, and perform better—by solving complex production challenges through intelligent automation, digital transformation, and engineered precision. From tooling and mechanical fixtures to turnkey automation, we engineer solutions that scale, flex, and deliver lasting performance optimisation.

Why partner with us?

Increase productivity and consistency

Eliminate production risks

Make faster, better decisions

Accelerate product and process changeovers

Reduce downtime and maintenance costs

De-risk production ramp-ups and NPI

Streamline operations and remove defects

Access rapid, agile solutions

We leverage AI-driven automation and data for process optimisation.

Precision engineering ensures reliable fixtures, tooling, and safety solutions.

Gain actionable insights from real-time process data.

Benefit from our flexible, modular system designs.

Our predictive technologies provide intelligent asset management.

Rely on our proven expertise in regulated sectors.

Implement smart, connected digital workflows for efficiency.

Partner with an industry leader for diagnostics and deployment.

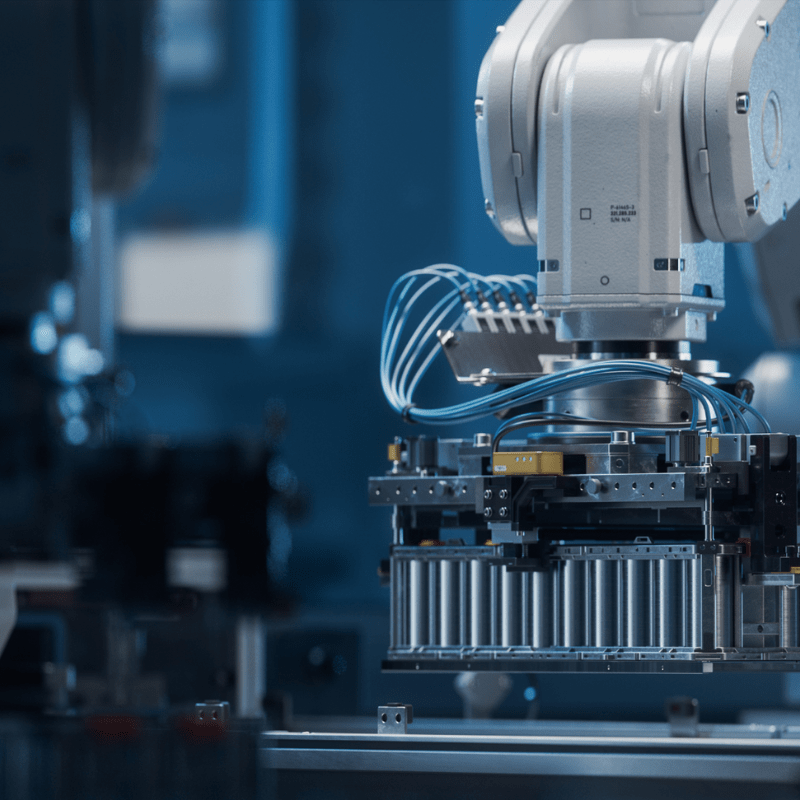

Scalable systems that automate physical and safety-critical processes.

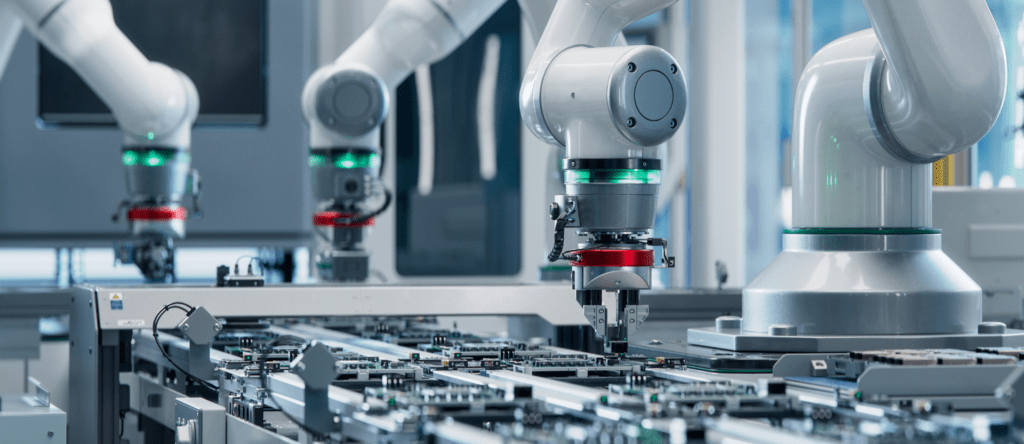

MetLase designs and integrates scalable automation systems engineered to optimise manual, safety-critical industrial processes. Our modular, technology-agnostic platforms integrate advanced AI that adapts in real time to changing operational demands—maximising throughput, minimising downtime, and optimising performance.

Interested in automation solutions? Speak to an expert.

Turning manual operations into high-performance, data-driven processes.

We design intelligent, digitally integrated systems that reduce variability and unlock faster, more consistent performance in complex industrial environments. By digitising manual, human-dependent processes, our platforms enhance operator decision-making, streamline workflows, and improve production visibility.

Our digital systems integrate smart sensors, AI, and connected technologies to streamline workflows, enhance measurement and verification, and optimise every process step.

Integrated digital solutions provide the right balance between standardised processes and the ability to customise products and respond quickly to manufacturing process changes by integrating process optimisation technology.

SmartBench digitises manual, repetitive assembly tasks—eliminating errors, reducing training time, and delivering real-time insights to drive better performance.

With guided workflows, integrated validation sensors, and modular design, SmartBench transforms manual operations into scalable data-driven manufacturing processes.

SmartBench lays the foundation for smarter manufacturing—enabling faster NPI, process flexibility, higher efficiency, and continuous optimisation in the most demanding production environments.

Want to see SmartBench in action? Request a demo.

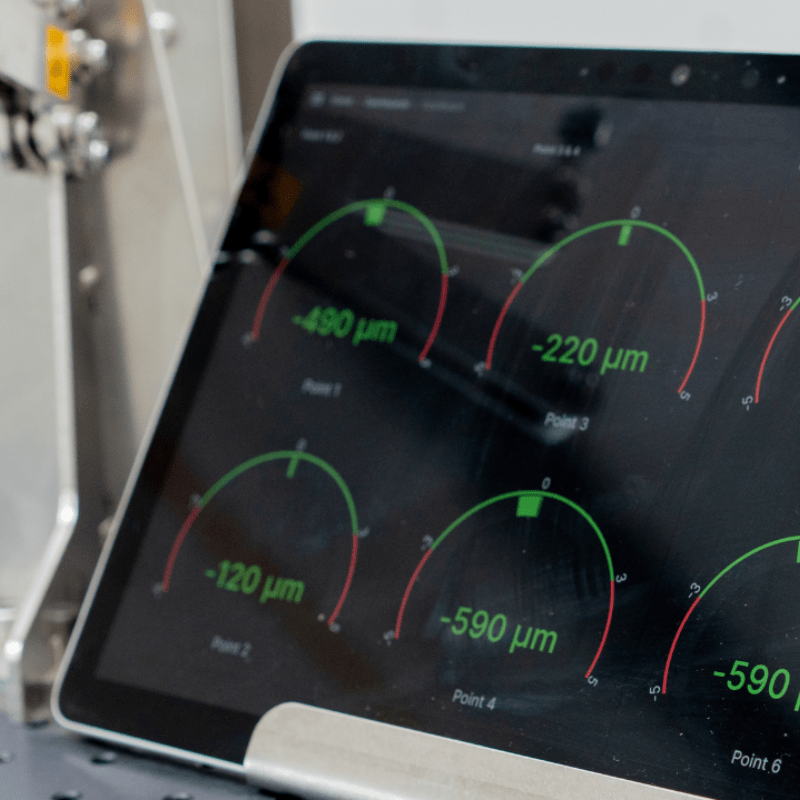

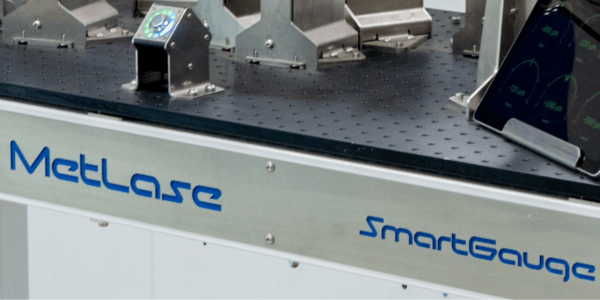

SmartGauge is a digitally-enabled, sensor-rich inspection product that streamlines, accelerates, and improves manual inspection processes. Integrating seamlessly with manufacturing lines, this technology eliminates manual checks and recording by providing real-time data analysis and visibility, reducing inspection time from hours to seconds.

SmartGauge empowers operators with actionable insights and real-time feedback, driving efficiency, reducing waste, and enabling continuous improvement.

Ready to implement SmartGauge? Contact us for a quote.

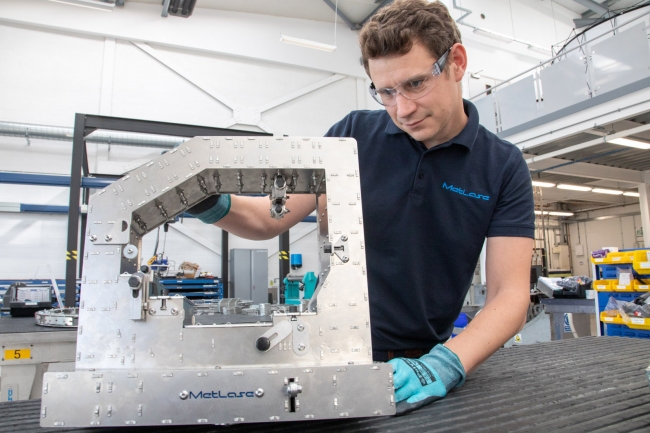

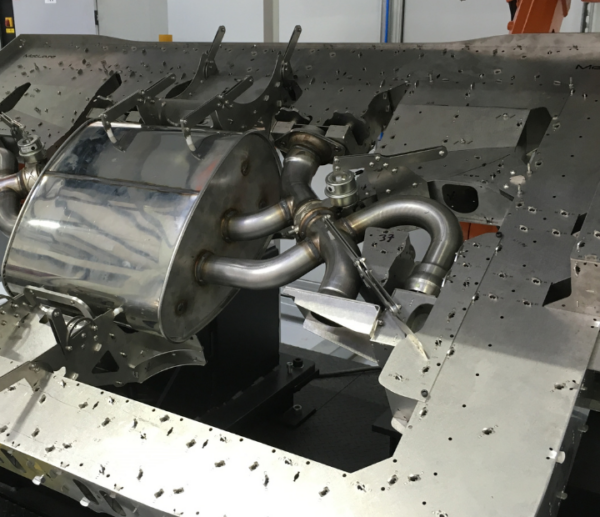

Precision assembly and tooling systems for complex manufacturing.

We deliver high-precision assembly fixtures and modular tooling systems engineered for complex, high-integrity manufacturing. Designed for low-to-mid volume and regulated sectors, our mechanical solutions address industry specific production challenges, enabling flexible, consistent, and repeatable performance.

From NPI to production ramp-up, we help solve time-critical and safety-sensitive assembly and metrology challenges—ensuring quality, process stability, and reduced risk.

Combining engineering expertise with data-analysis, to triage your process and shape the right solution for you.

Our technical diagnostics service uncovers the root causes behind process inefficiencies—giving you clarity before investment.

By taking a collaborative, consultative approach, we identify the real business challenge and shape the right solution from the outset.

Combining our engineering expertise with data-driven analysis, we triage your operations, isolate inefficiencies, and co-develop the right solutions for you.

Your solution awaits. Contact us today.