Not every Printed Circuit Board, or PCB, needs to be replaced. We specialise in the PCBs commonly used in electrical and electronic goods, repairing and renewing over 91.43% of failed units through our reverse logistics. This extends asset life to cut warranty costs, reduce waste, and keep your customers online.

Our proven solution transforms aftermarket operations from warranty cost centres into lean, efficient renewal programmes that deliver measurable commercial and environmental benefits, driving your sustainability goals.

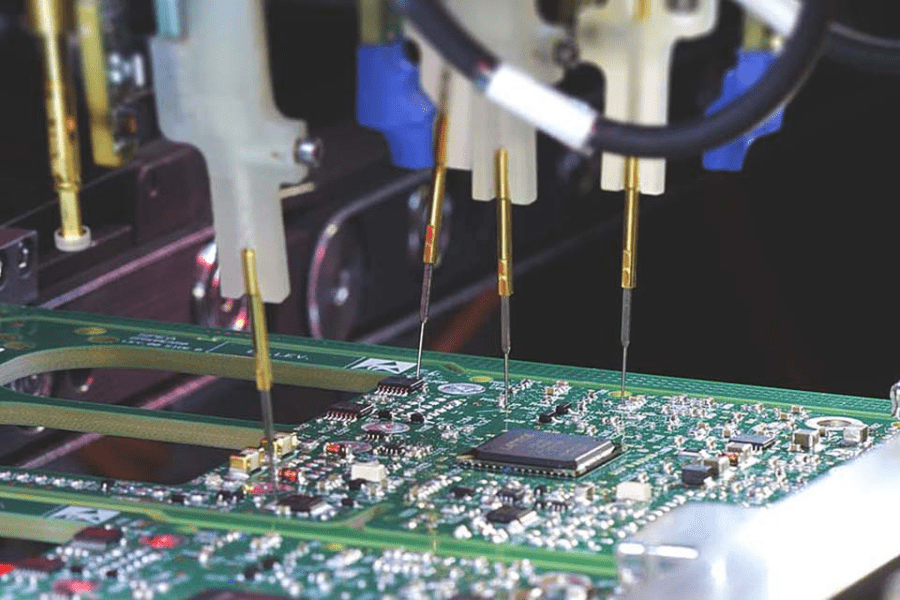

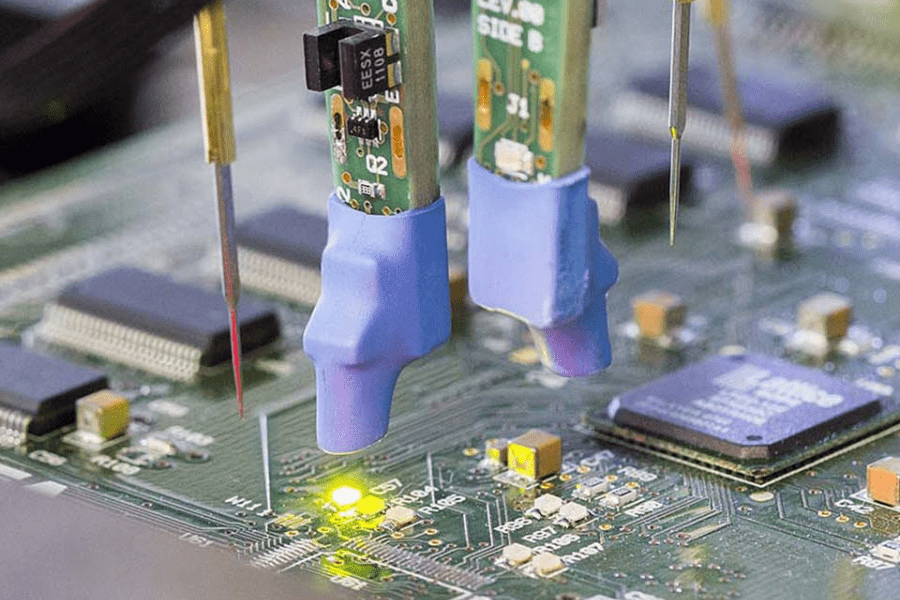

Thermal cycling, corrosion, vibration, and electrical stress are the most common causes of PCB Failure, but they don’t mean it’s the end of life for the board. Our team of expert engineers go further to renew PCBs, including those once considered “unrepairable.”

Long warranties often mean rising PCB replacement costs and reputational risk. Our service protects your budget and brand and maintains installer confidence.

For kitchen equipment, a failed PCB means downtime and lost revenue. We help you get customers back online fast.

Unipart’s PCB Renewal Lab is transforming aftermarket operations, helping OEMs turn costly warranty programmes into efficient, sustainable asset renewal systems.

Ready to reduce warranty costs and improve sustainability?