The UK has seen rapid growth in Battery Electric Vehicle (BEV) adoption, with over 1 million BEVs registered since 2002.

This growth is accelerating, with BEVs accounting for a significant 19.6% of new car registrations in 2024 (SMMT, 2025), reflecting increased sales and a rising number of EVs on the road.

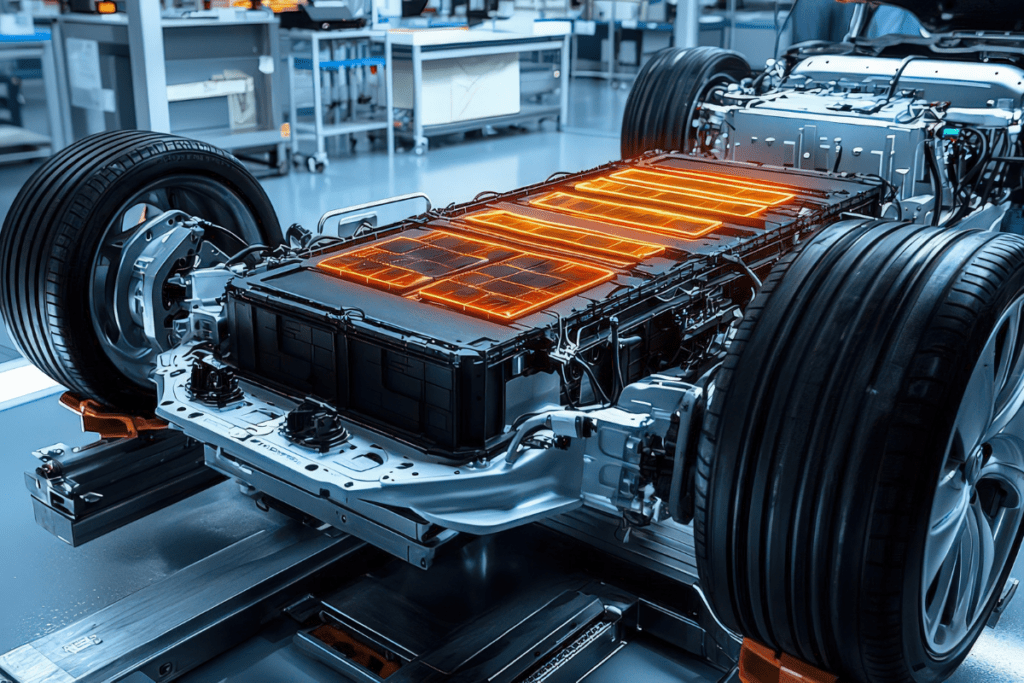

We are leading the charge in full end-to-end EV battery services, from manufacture, storage, delivery, remanufacture, repurpose and managing the battery end of life, we are your single partner throughout the process. We focus on cost-effective, scalable, and sustainable solutions to help companies navigate the transition to electric vehicles.

Our global presence allows us to support OEMs looking to expand their presence into new regions, developing an end-to-end capability on a global scale.

Why Unipart is your perfect partner to support you in navigating the electrification revolution.

Manufacturing heritage

Industry-leading battery technology

Proven supply chain expertise

Compliance & regulatory readiness

Sustainability

40 years of manufacturing excellence in safety-critical systems.

Scaling electrification requires not just making batteries, but keeping them in service, reducing waste, and improving sustainability.

Scalable manufacturing, production, aftermarket and circular EV supply chain services.

Fully compliant with IATA air freight, ADR road & IMDG sea regulations.

Actively driving sustainability in EV to drive environmental, economic and resilience benefits, aligned with Net Zero and circular economy goals.

Unipart offers the UK’s only fully integrated full battery lifecycle solution, spanning design, manufacturing, remanufacturing to restore battery performance, repurposing for second-life applications, and recycling to recover valuable materials, reducing costs and waste for OEMs and fleet operators.

Unipart bridges the gap to offer seamless, scalable, and compliant solutions that extends battery life, reduces waste, and lowers Total Cost of Ownership (TCO).

In plant logistics

Unipart uses the latest automation for in-plant logistics for battery pack assembly, offering just-in-time storage and sequencing solutions.

Transport

Our expert teams support safe, reliable, just-in-time global logistics of lithium-ion packs, compliant with IATA, ADR & IMDG regulations.

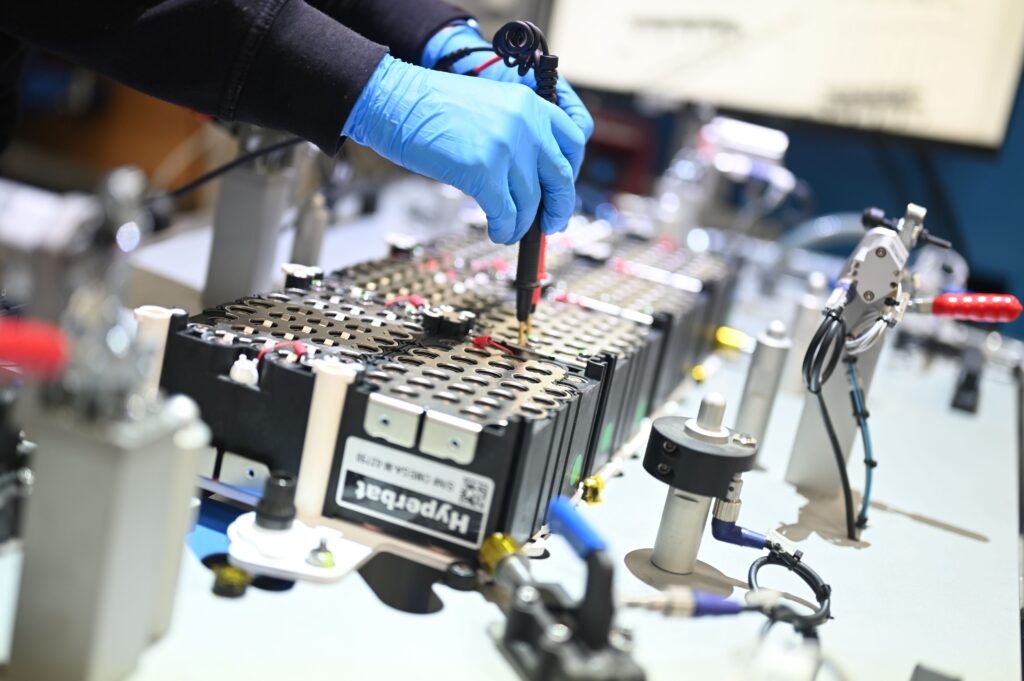

Test and triage

Our 'Test & Triage' capability assesses EV battery health, capacity, & performance, categorising each for reuse or recycling.

Repair & remanufacture

Our remanufacturing process provides a defined solution for battery failure, extending the primary lifecycle of the EV battery.