A digitally optimised slim floor system combining laser-cut sheet steel, reinforcement, and low-carbon concrete to eliminate downstands, reduce floor depth, and integrate services within a structure.

Designed to maximise usable space and simplify installation, SFB cuts embodied carbon by up to 65% compared to traditional precast or in-situ floor systems.

Delivered precast and ready to install, SFB reduces installation time by up to 40%, minimising site labour and eliminating emissions from on-site casting. Each beam forms its own mould, negating issues with early strength development and enabling the use of lower carbon concretes.

Compatible with all major slab and column types, SFB offers flexible connection options for faster, more efficient floor construction across residential, commercial, and infrastructure projects.

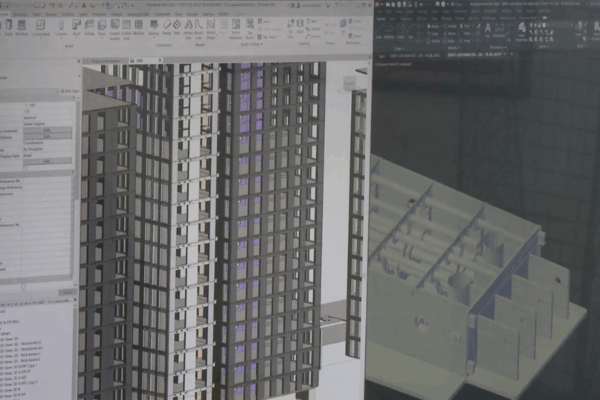

PCE Ltd integrated the Slim Floor Beam into their hyTowerⓇ system to deliver the Fulton & Fifth build in conjunction with Arada London, ensuring optimal use of materials for structural performance, aesthetics, and sustainability.

For low-carbon construction and faster, safer installs

All of our construction technologies are digitally engineered and manufactured offsite to optimise the delivery of modern construction programmes.

Combining speed, certainty, sustainability and control, our systems accelerate installation, reduce embodied carbon, and eliminate complexity on site.

Each product is backed by parametric digital design, precision manufacturing, and logistics integration. Together, these industrialised solutions reduce programme risk, improve quality, and create measurable value in time, cost and carbon across commercial and residential builds.