We replace fragmented workflows with digital design, offsite manufacturing, and Just-in-time logistics to simplify on-site activity for faster, safer builds.

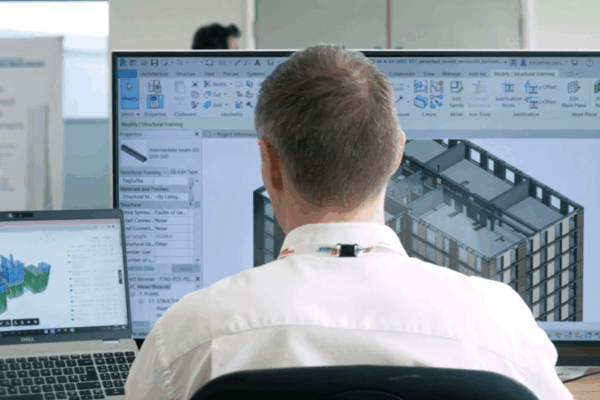

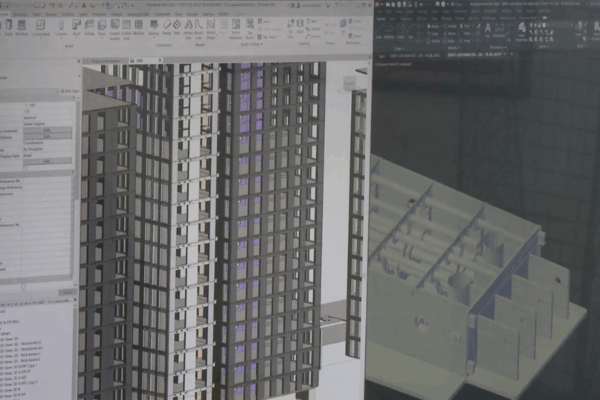

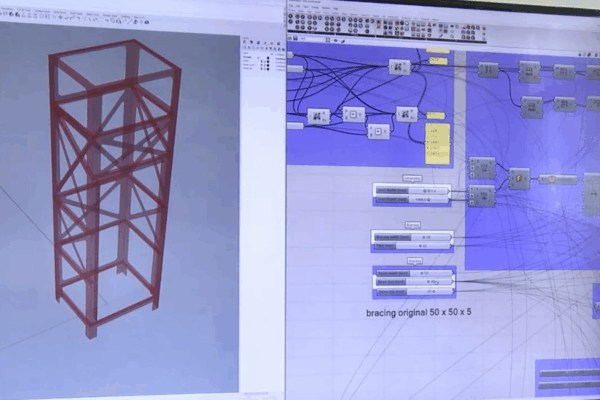

Faster design: Advanced digital tools cut design time by up to 50%, enabling faster, more accurate outputs and early cost and delivery certainty.

Just-in-time productivity: Final-mile logistics and precise sequencing ensure components arrive on time every time, reducing delays and boosting efficiency.

Rapid, low-risk installation: Factory-built systems like MEP and MRS install up to 40% faster than in-situ options, minimising on-site complexity and programme risk.

We deliver programme, cost, and quality certainty, utilising digital tools and backed by industrial standards proven across Unipart’s global, safety-critical operations.

Digital design accuracy: Parametric modelling ensures project specific precision, manufacturable outputs and material, cost and carbon accuracy,

Industrial process control: SCADA-enabled production environments ensure full traceability and digital control for consistent right-first-time quality at scale.

Delivery assurance: Integrated logistics and multi-tier sourcing strategies protect programme schedules and reduce disruption.

Safer outcomes: Offsite solutions reduce high-risk site activities, enabling safer, more controlled construction environments.

We help the industry build smarter and more sustainably, reducing embodied carbon, optimising material usage and improving supply chain efficiency.

Low-carbon materials: Offsite manufacture supports the use of low-carbon concrete and green steel, cutting emissions at source.

Carbon-optimised design: MRS cuts embodied carbon in reinforced concrete by up to 65%; MEP Frames use up to 30% less steel.

Cleaner manufacturing: UK-made components using 100% renewable energy, reducing transport emissions and boosting supply chain resilience.

Sustainable logistics: Just-in-time delivery and shipment consolidation reduce mileage, site waste, and transport emissions.

We transform the entire construction process, from digital design to on-site installation, by embedding industrial-grade control, real-time data, and a connected digital thread that links every stage of delivery.

Connected workflows: Seamless digital integration from design to fabrication and installation eliminates delays.

Error-free production: Parametric design outputs feed automatically into manufacturing processes, for rapid, right-first-time production

Real-time visibility: SCADA systems and logistics control towers provide real-time visibility and performance across the supply chain

Full traceability: Every component tracked and verified from 3D design model to on-site installation.