Slashing component costs by 80% with circular engineering

8th August 2025 | 60 sec read

The Challenge

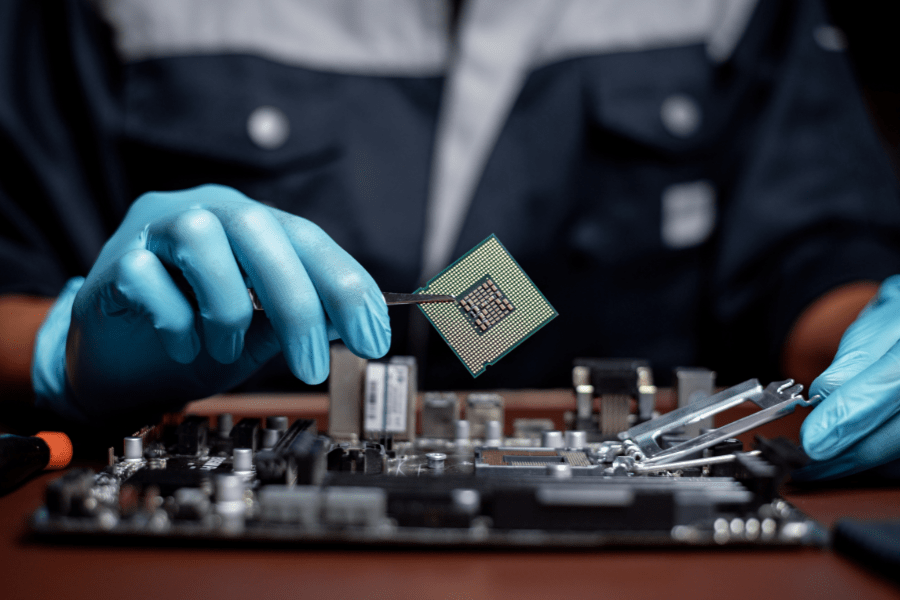

A leading home services provider was struggling with a monopolistic supply chain for domestic boiler spares. Valuable components like printed circuit boards (PCBs) were being scrapped in high volumes, driving up costs and environmental waste.

The company needed an innovative and safe way to disrupt this model and create a competitive advantage through a more sustainable, circular approach to asset management.