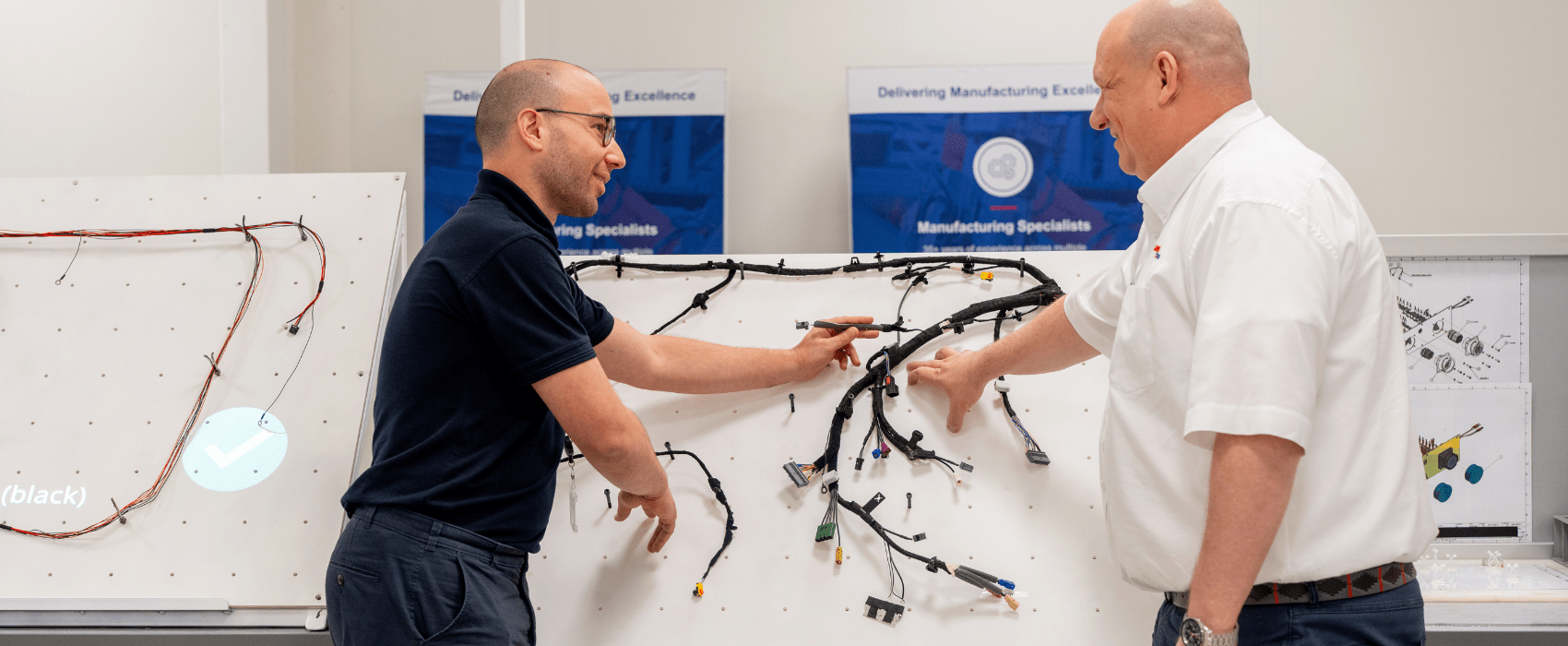

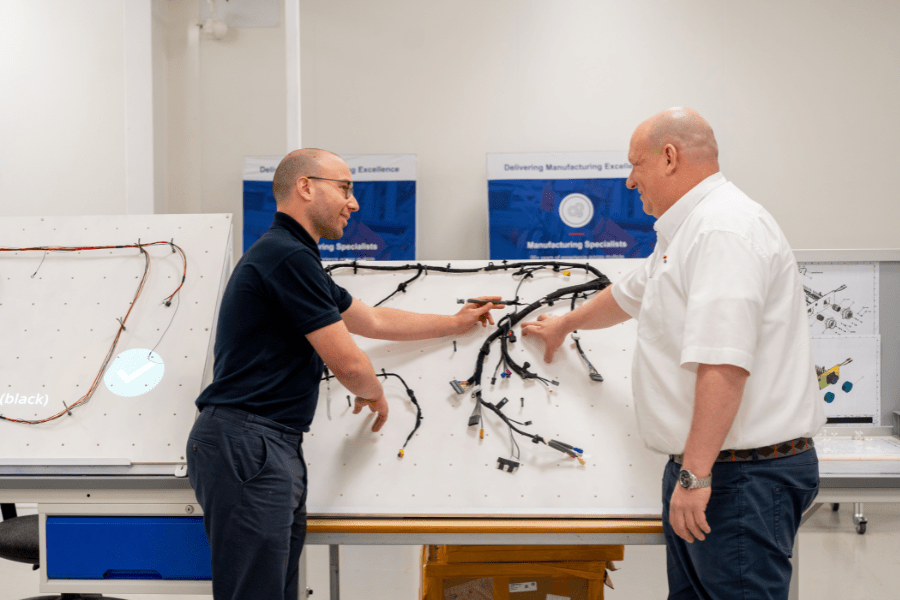

Precision-engineered wiring harnesses for high-performance automotive applications

8th August 2025 | 2 min read

The Challenge

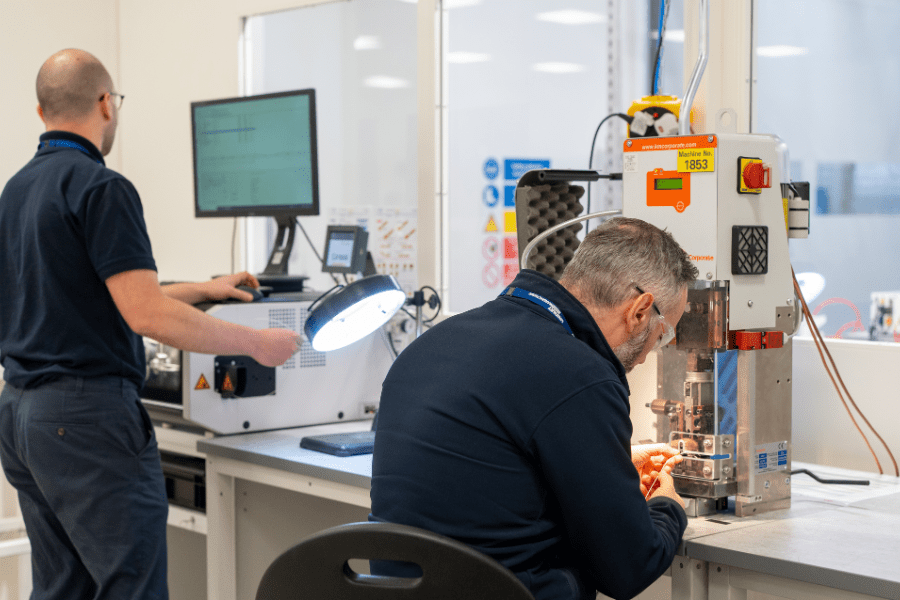

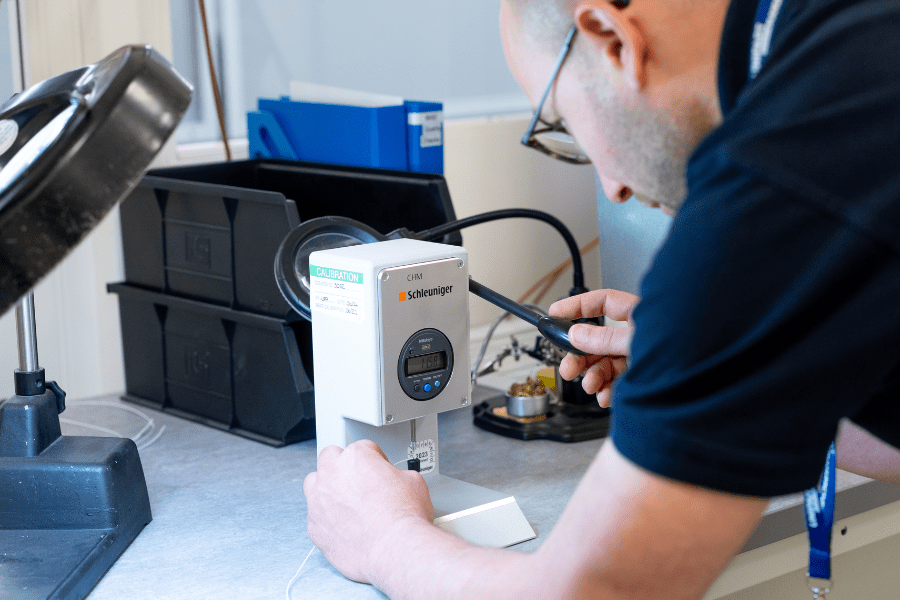

Hyperbat, a leading EV battery manufacturer, required a high-precision, safety-critical wiring harness solution for a high-performance automotive application. Existing suppliers struggled to meet the required stringent quality standards, full traceability, and manufacturing consistency, leading to supply chain inefficiencies, quality concerns, and production delays.

To address this, Hyperbat sought a trusted UK-based manufacturing partner with proven expertise in automotive-grade assembly, process control, and zero-defect manufacturing. The ideal supplier needed to deliver flawlessly, scale production seamlessly, and integrate with Hyperbat’s evolving engineering requirements.