Multi-site manufacturing business identifies £90,000 cost savings using EI.

17th December 2025 | 2 min read

The Challenge

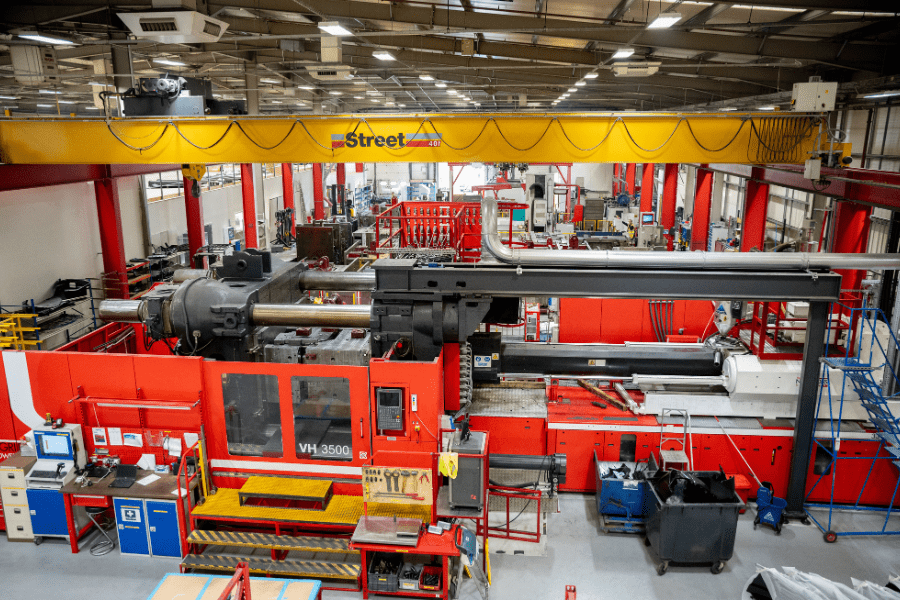

A multi-site component manufacturer operating high-load production equipment faced rising energy costs that were putting pressure on operational margins.

With ageing machinery, variable shift patterns and limited real-time insight into asset performance, the business required a solution that could:

- Reduce energy waste without disrupting production

- Provide rapid, measurable savings within the first year

- Deliver visibility for leadership, finance, operations and maintenance

- Retrofit quickly and easily across existing machinery, avoiding significant capital expenditure.

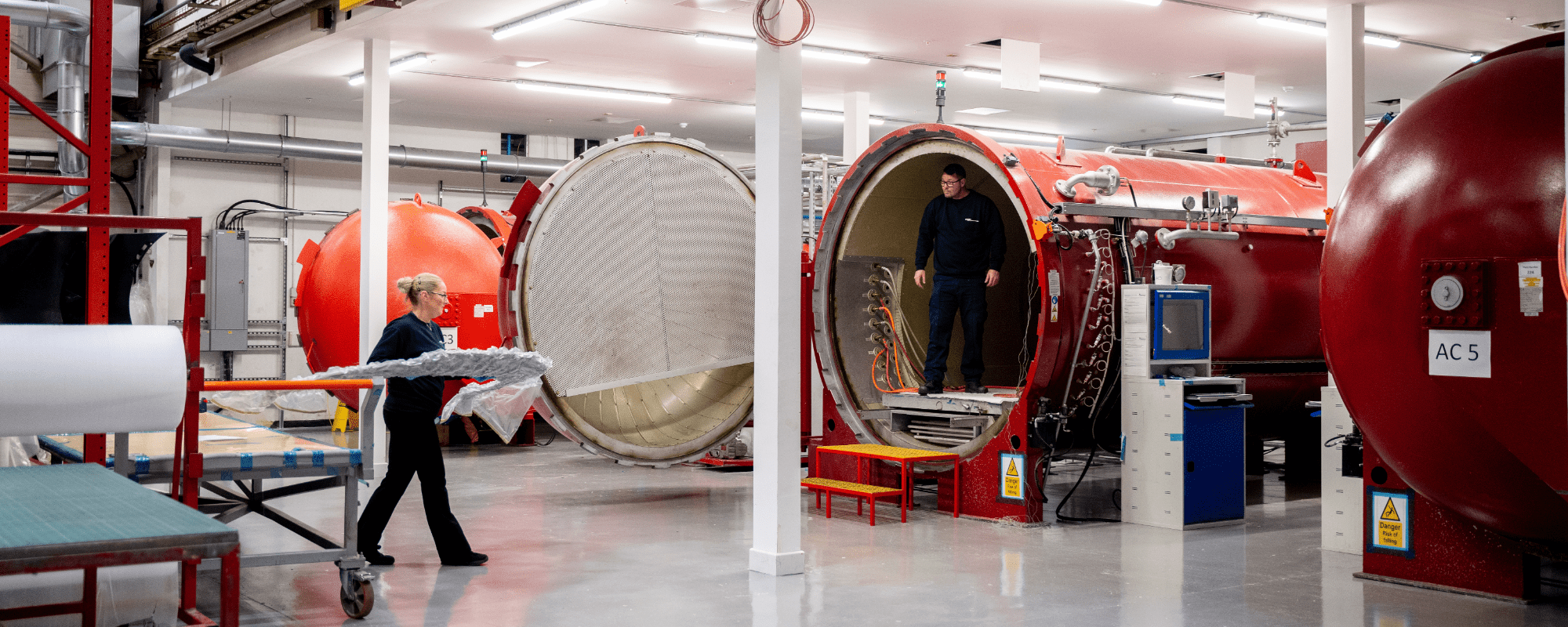

Like many SME manufacturers, they needed control, not just data, and clear insight into where energy waste was occurring across their curing, painting and composite processing lines.