The Impact

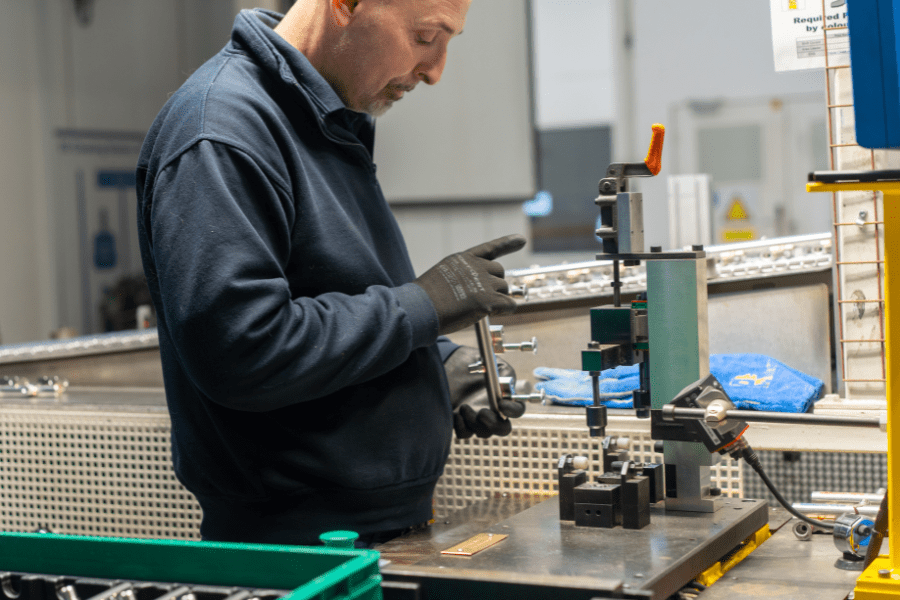

Unipart’s approach is built on a culture of manufacturing excellence, lean thinking, and continuous improvement, ensuring processes never stand still. Every investment, from automation to advanced traceability, is made to deliver greater efficiency, consistency and value for customers.

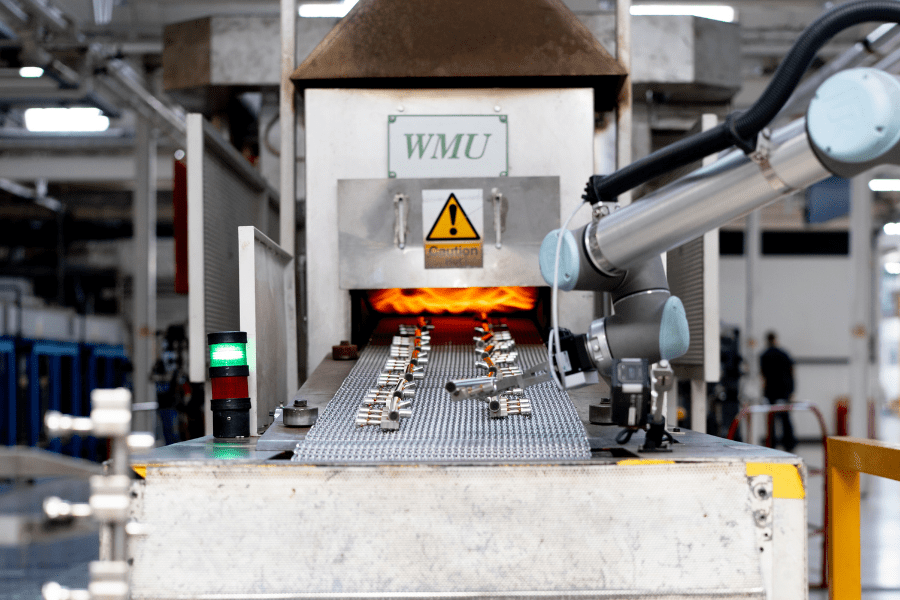

The furnace brazing facility has delivered sustained, high-quality production over more than a decade, achieving consistently excellent delivery performance and zero critical quality concerns. The customer extended its contract – which included exporting fuel rails competitively to China – in recognition of Unipart’s quality, reliability and engineering partnership.

This proven and competitive capability is now available for sectors beyond automotive, including aerospace, defence, rail, HVAC and energy systems, offering:

- Scalable UK-based manufacturing to reduce supply chain risk

- Proven expertise in safety-critical applications

- Flexible capacity for both high- and low-volume production

This mindset of refining processes and embracing innovation ensures that Unipart’s manufacturing capability will continue to evolve, meeting the future needs of customers across multiple sectors.