Elevating rail connectivity with automotive-grade wiring harness manufacturing

8th August 2025 | 3 min read

The Challenge

As part of the UK rail network’s digital transformation, a critical order for replacement Train Protection & Warning System (TPWS) units was required. TPWS units, which have been in service for over 20 years, are safety-critical systems that automatically apply a train’s brakes if it’s travelling too fast on approach to a signal or if it passes a red signal (Signal Passed at Danger, SPAD).

This upgrade specifically involved the manufacturing of specialised wiring harnesses, bringing out the complexity of the project. However, the challenge extended beyond simply integrating the latest technology:

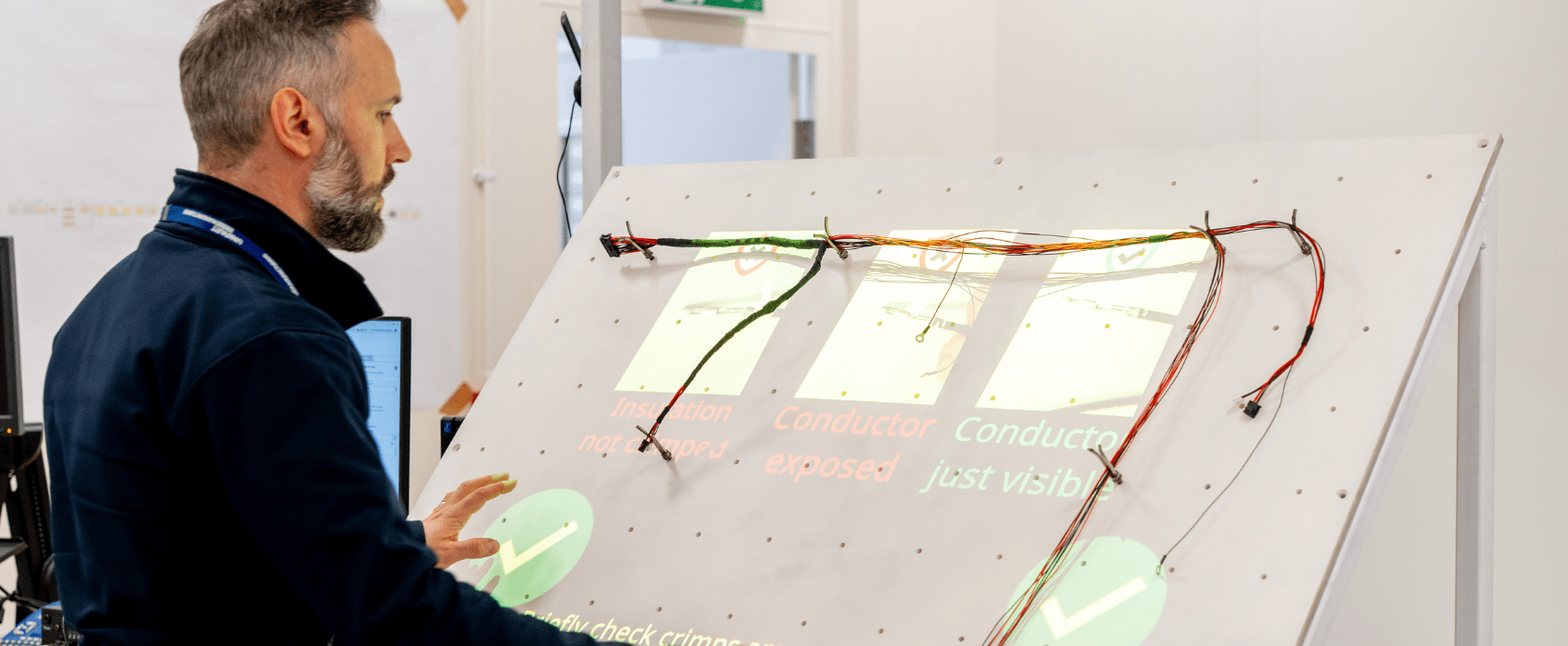

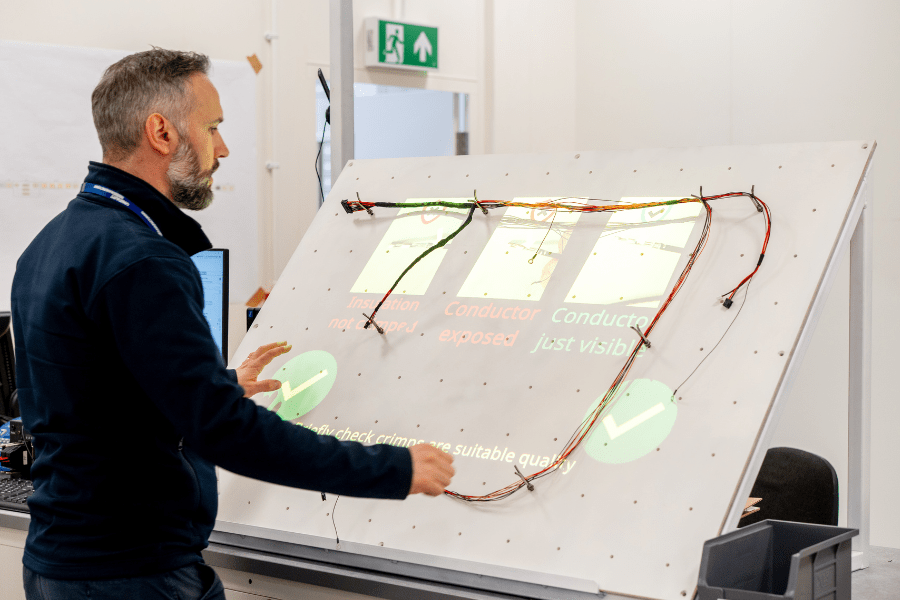

- The wiring harness needed to be designed for extreme environmental conditions, withstanding water, dirt, extreme temperatures, and constant vibrations over a 10-15-year lifespan.

- Rail manufacturing follows an over-engineered approach, ensuring durability and long-term reliability.

- The wiring harness solution had to integrate seamlessly with legacy systems, with some rail carriages over 40 years old, without the need for costly new designs.

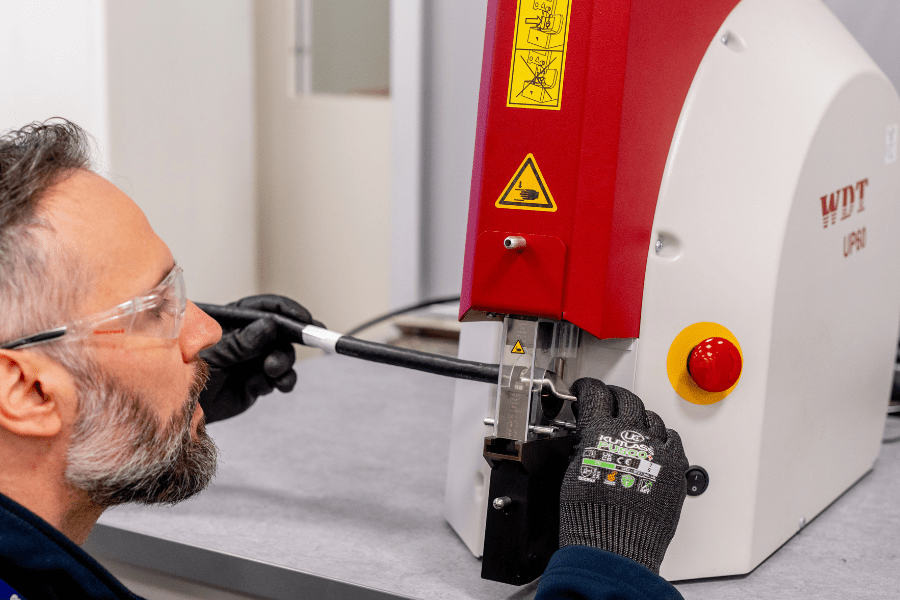

- Strict IPC620 standards for wiring harnesses had to be upheld while adapting to rail industry best practices.

To meet these demands, the rail industry needed a manufacturing partner to supply wiring harnesses that could combine rigorous quality control, high-precision assembly, and full traceability, without driving up costs.