EI. delivers £28,800 cost saving on high-volume automotive production line

18th December 2025 | 2 min read

The Challenge

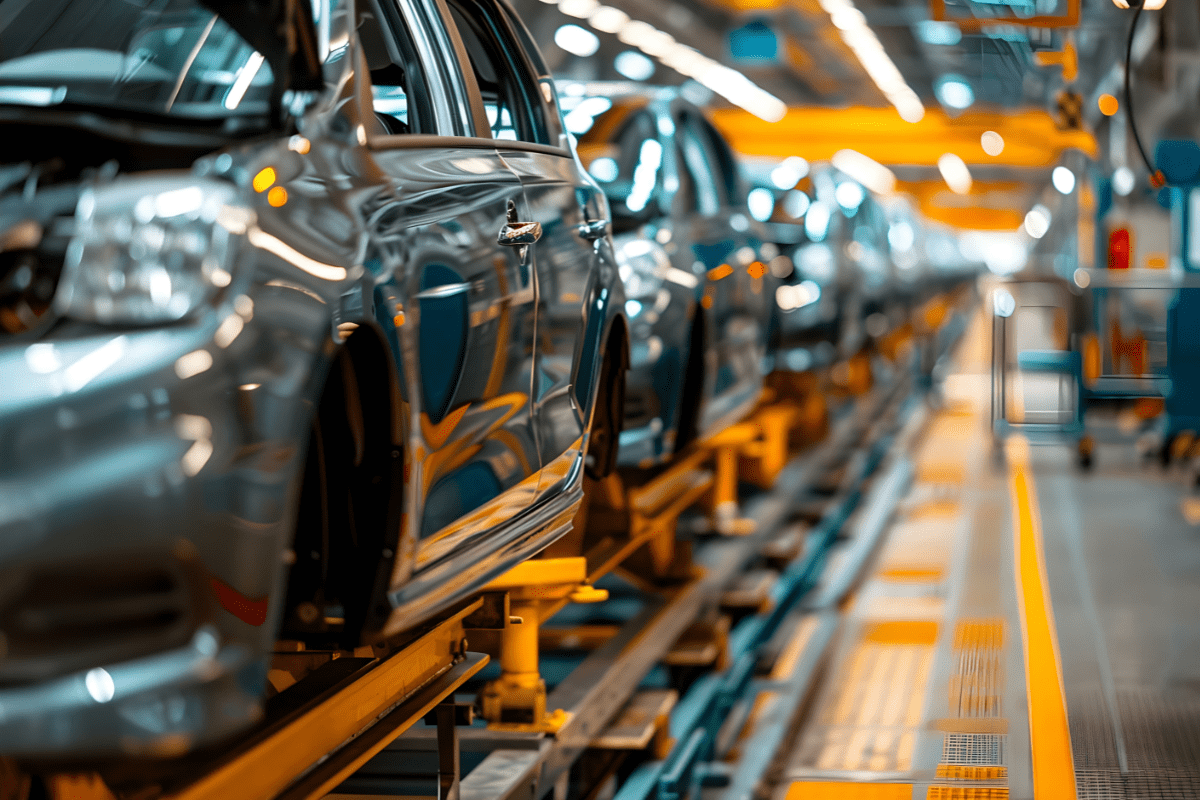

A major UK automotive manufacturer operating a high-volume production lines faced mounting pressure to reduce rising energy consumption and operational costs.

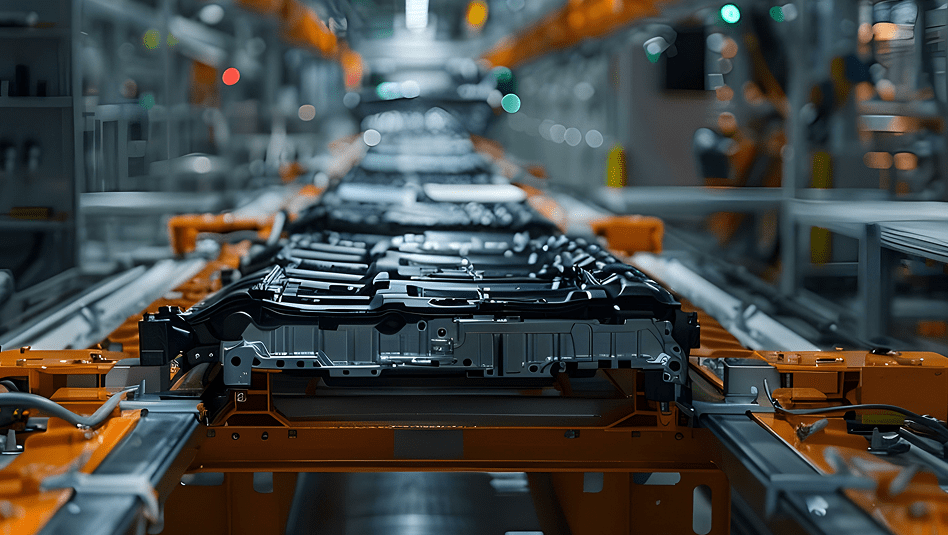

As the automotive sector transitions away from internal combustion engines, many established production lines are entering end-of-life. This makes capital investment harder to justify for OEMs and Tier 1 manufacturers, driving the need for low-disruption, fast-payback solutions that extend asset life and protect margins.

Like many manufacturing partners to the high-performance automotive industry, operations were experiencing:

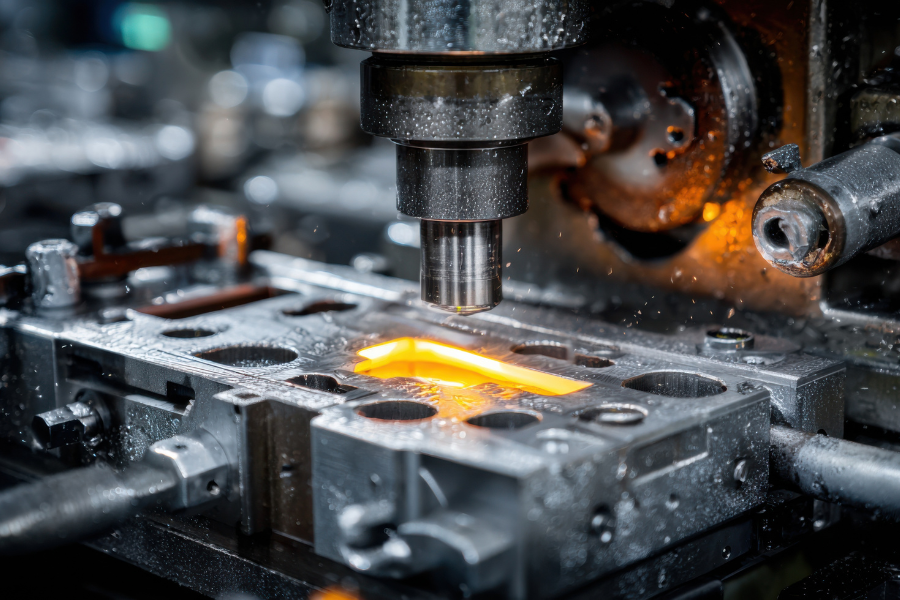

- Increasing electricity costs driven by energy-intensive thermal processes

- Ageing machinery with unknown idle and out-of-hours consumption levels

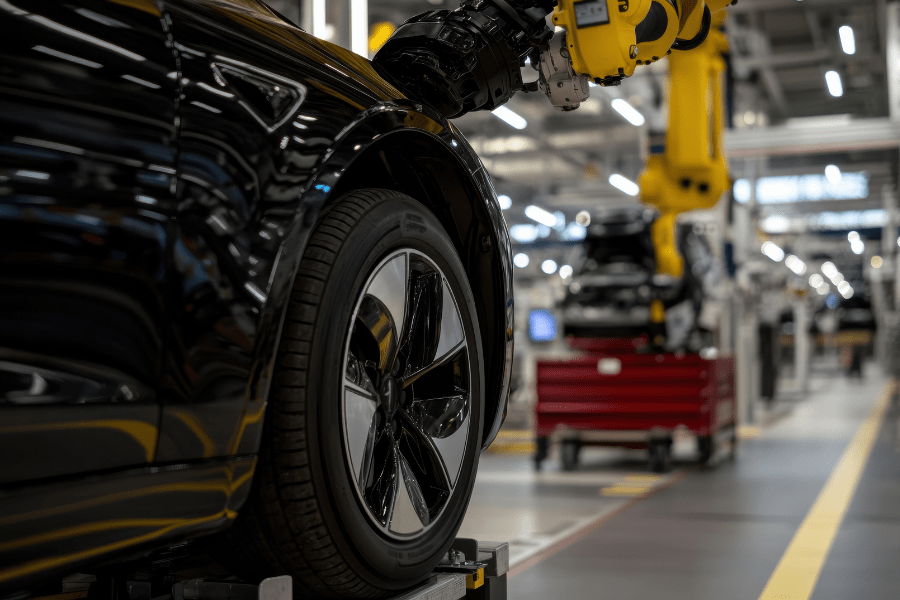

- Limited visibility of asset-level energy and performance behaviour

- Pressure to improve efficiency without pausing or impacting production throughput

To remain competitive, the manufacturer required real-time insights to expose hidden energy waste, direct investment and optimisation decisions and fast, measurable ROI.