The Solution

As part of the Clean Futures Accelerator Programme funded by the Connected Places Catapult on behalf of the West Midlands Combined Authority, Unipart, in collaboration with Coventry University, has developed a Net-Zero Manufacturing Digital Assistant – a powerful decision-making tool designed to accelerate sustainability in manufacturing.

This tool enables manufacturers to identify, assess, and prioritise carbon reduction strategies for existing production lines, improving energy efficiency and cost competitiveness while supporting net-zero goals.

The team worked closely with Coventry University at our Institute for Advanced Manufacturing and Engineering to deliver innovation and tools to accelerate net-zero initiatives across multiple production sites. The key outcomes included:

- A new bottom-up carbon calculation and mitigation planning tool

- Use of predictive analytics to identify cost-effective decarbonisation solutions

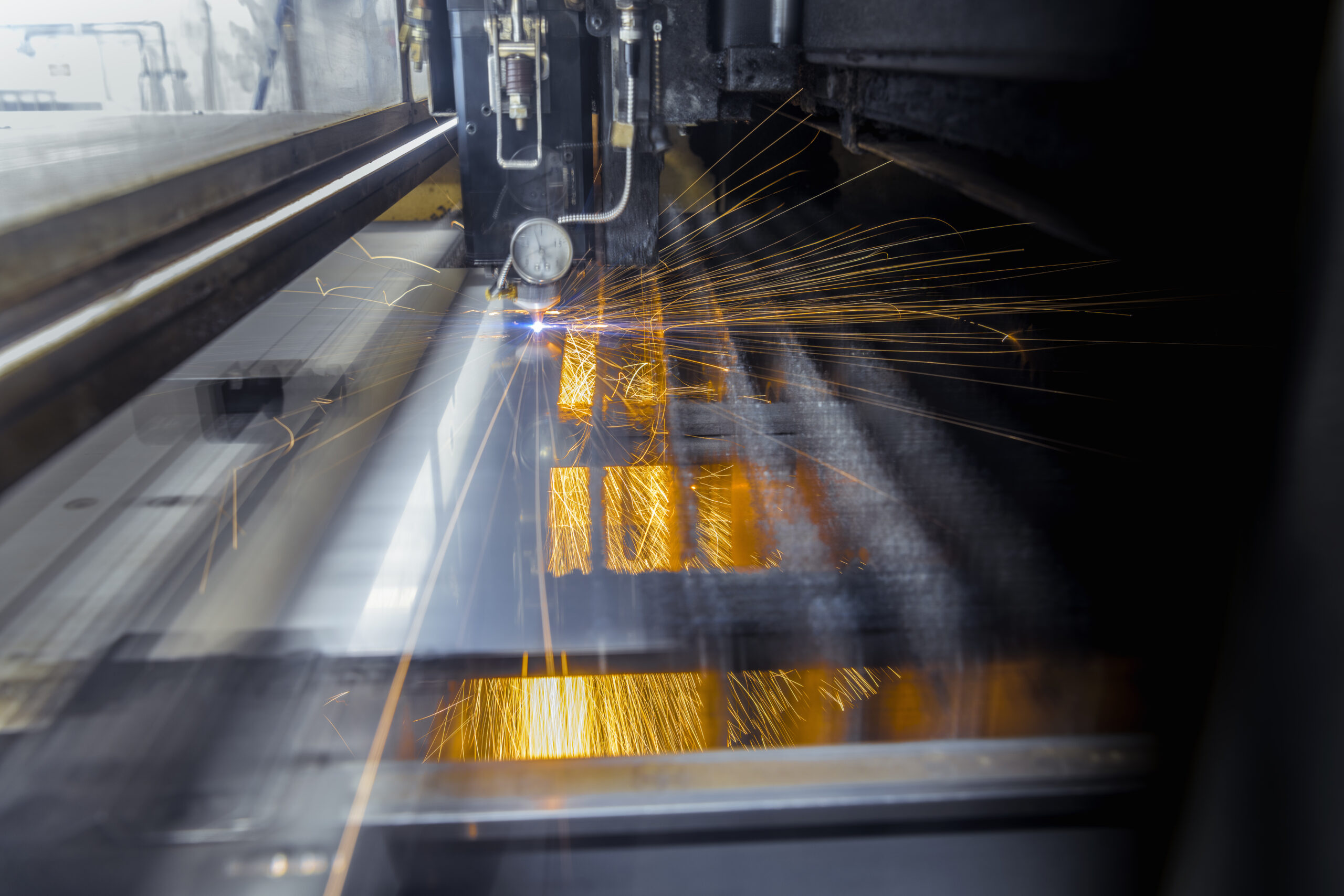

- Implementing a carbon intervention to Unipart’s furnace brazing line, providing auto night-mode functionality, advanced gas mix controls, and flue system upgrades

Measured improvements in energy consumption and costs following installation of Unipart’s energy monitoring system Eco Insight